Technology and the 15th century enamel has a close relationship Geneva, when the enamel technique is mainly used for jewelry, but with the rise of 17th century watchmaking industry, enamel technology has undergone a major change.

Vacheron Constantin is a small number of available enamel watch dial manufacturer. As the oldest, never stopped the production of watches and clocks manufacturer Vacheron Constantin in Geneva the previous succession passed down the most precious ancient process and, therefore, incumbent upon these rare "saving" technology heritage and carried forward. Enamel this material can not only meet the extremely rigorous process and achieve swatch results, and can stand the test of time, not oxidized, but also for the good of the dial design adds depth and luster. Entirely by hand, each dial are made according to traditional processes, each minor parts are flawless, only a few experts can make such a fine enamel effect. Enamel to make the best effect, need to dial the fire in the nearly 800 ° C high temperature firing 5 to 7 times. In order to prevent cracks in the heating process, must have added a layer of glazed enamel layer of the lower dial. In each of the firing process, these processes may lead to rupture, or even unexpected results emerged. Grand Feu enamel technique is brought Vacheron Constantin glory for centuries, through these new watch model, Vacheron Constantin once again show the world that culminated in process.

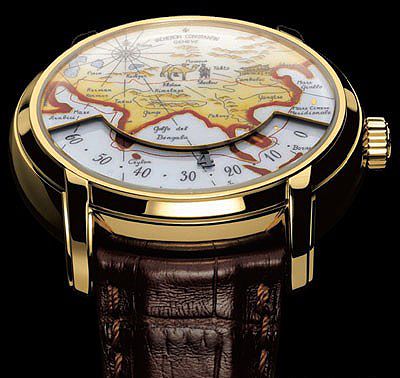

In 2004, Vacheron Constantin launched to commemorate the Portuguese explorer Ferdinand Magellan and the Chinese navigator Zheng He of the two watches. Enamel paint on the dial to the two explorers discovered area. Four years later, Vacheron Constantin, the world once again to the other two famous traveler - Marco - Polo and Christopher - Columbus tribute.

Normal enamel can not drink coffee or tea, of course, can not smoke in a word, any thing containing stimulants can not stick mouth. Hand must always remain swatch, and have full control of every action and accurate. This is the first lesson of every discipline enamel teacher's first lesson learned in the Code. Is well known that enamel process is one of the most demanding process, it is the most important discipline. Throughout history, or only the hand-painted medieval Europe, the draft lighting division skills in practice only when the enamel should be as strict division so as to comply with the rules. When the enamel Vacheron Constantin division to receive the memory of the famous explorer and launch Métiers d'Art Explorers series of instructions, they start to taper with a metal pen, only half a micron thick and 24 microns wide 22K metal, and outlined what he wanted to paint. Sometimes, he will groove with a carving knife in the crafts cut out some obvious groove, to accommodate set enamel.

Enamel Division in the production process will use a powerful amplification with binoculars, and then one by one or two made of mink oil sweep to the right on the dial on the enamel drops. Color used should follow a strict order of pre-set. Then, this craft will be put into a 700 to 800 ℃ of the kilns in the sintering. Cooling and then polished, and sometimes use the diamond to polish. Each have to make several crafts glazed, sintering, polished and polished, to do the dial up to 30 times each. Sintering time used in the light of the type and amount of enamel may be, and must bring Niede accurate, so enamel Carpenter often not easily tell others the sintering time. In the final stage, the enamel artisans will craft a layer of transparent coated with flux, and then into the kiln temperature of 900 ℃ burn once more. After cooling, the dial need to grind and polish after the last time before they handed over to watch assembly member assembly. Long and rigorous process of making really distracting, and enamel are also easily broken. When it left the kiln, in the cooling process may be due to sudden changes in temperature, fragmentation, and this will enamel division wasted countless hours spent before and efforts. Therefore, the process heat must be very slow, careful and regular manner.

Article Source: http://www.vogue-element.com

Related Articles: Vacheron Constantin Métiers d’Art Les Masques Watches in 2011

No comments:

Post a Comment